Product description

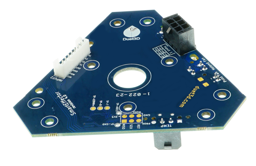

The Duet3D Filament Monitor very accurately senses filament movement. Connect it to a Duet 2 or Duet 3 and the controller will use the indicated movement to determine a wide range of extrusion issues including:

Filament run out Extruder skipping steps Nozzle starting to jam (causing skipped steps or grinding) Filament beginning to grind in the extruder

It does this so accurately because it is effectively an extruder in reverse. The filament movement rotates a custom machined hobbed magnet assembly; the magnet rotation is sensed and constantly reported to the Duet. This method has proven extremely accurate across a wide range of filaments – frequently capable of pausing the print before a filament jam or other issue has already caused the print to fail.

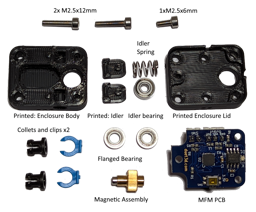

Kit: The monitor is available as a kit excluding the printed housing (we provide a design).

Assembled: Fully assembled in a MJF printed housing.

Both versions include a connector pack with the Molex-KK-style housings and crimps to connect the monitor to the Duet board.

Documentation

| Installation | GO TO DOCUMENTATION > |

| Configuration | GO TO DOCUMENTATION > |

RELATED PRODUCTS

The Smart Effector for delta printers allows the hotend to be used as a Z probe giving fantastic accuracy across the whole delta build area by eliminating the effect of tilt.

An advanced, high power controller that features 6x 6.3A stepper drivers, 4 high current heaters, 6 fans and more

An advanced, high power controller that features support for 6 external stepper motor drivers, along with similar outputs and IO as the Duet 3 Mainboard 6HC.

An advanced, mid range controller that features 5x 2A stepper drivers, 3 high current heaters, 4 fans and more.

The Duet 3 Tool board: a CAN-FD connected expansion board for Duet 3, designed to provide complete control for a direct drive extruder.

The Duet3D Roto Filament Monitor integrates tightly with the Duet 3 Roto Toolboard and accurately senses filament movement to detect clogs, filament run out and other extruder issues.